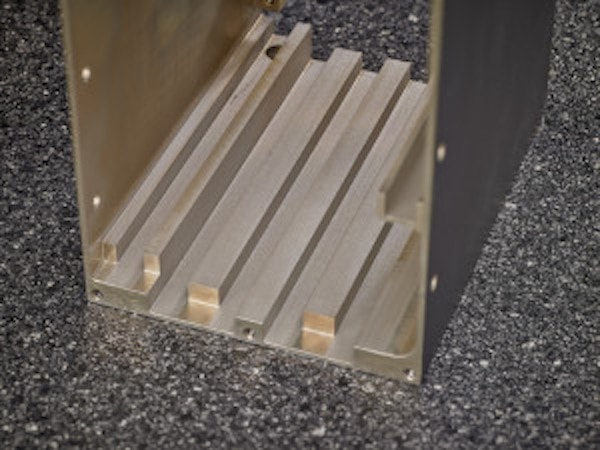

This housing assembly holds circuit boards in the aerospace industry and presented a unique opportunity for our EDM department, bulk material removal while creating the card slots. In our preplanning stage we determined that by going on the 5 axis mill for two operations, establishing datum edges and cutting in some strategic locations we could then go to the EDM.

Using our new Makino U3 Heat EDM we not only finished the card slots but removed over 90% of the parts raw material weight at the same time.