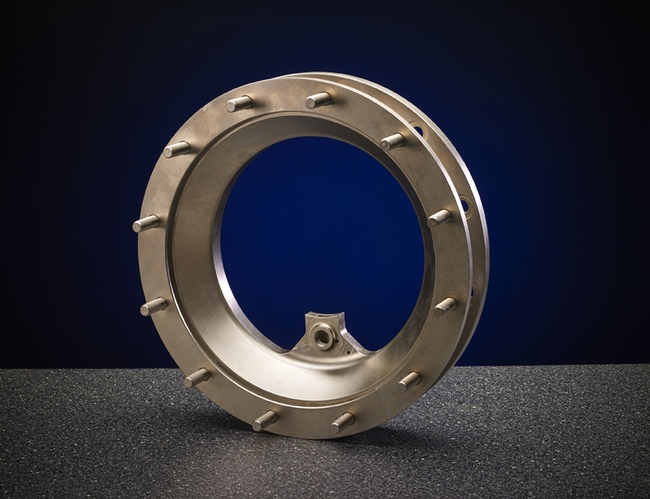

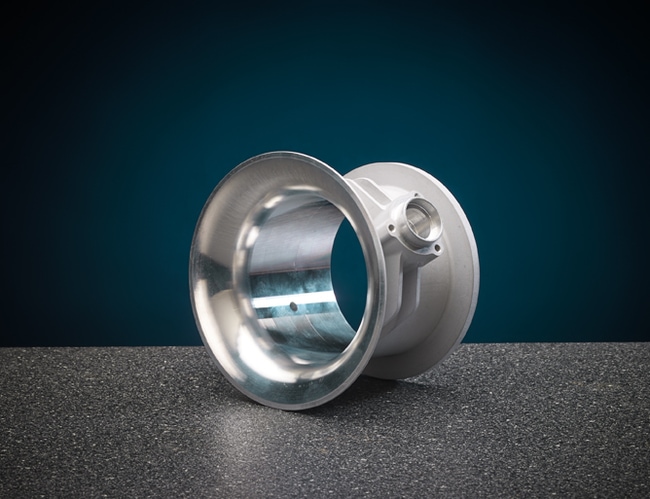

At Mac Machine Company, our team has over 40 years of experience creating high-quality, extremely specialized parts for aerospace, medical, and military applications. We provide turnkey services for complete machining project management. Our facility has the equipment, manpower, and expertise to turn even the most complex design drawings into reliable components from a wide variety of metal and composite materials.

Our Turning Capabilities

Turning uses cutting tools to remove excess material from rotating workpieces to meet various design specifications. At Mac Machine Company, we specialize in computerized, automated CNC turning systems that can produce high-volume orders within tight tolerances. Our team can produce goods ranging from customized fixturing to medical instruments and everything in between. Our machines also cut bearing liners and gear splines to exact specifications.