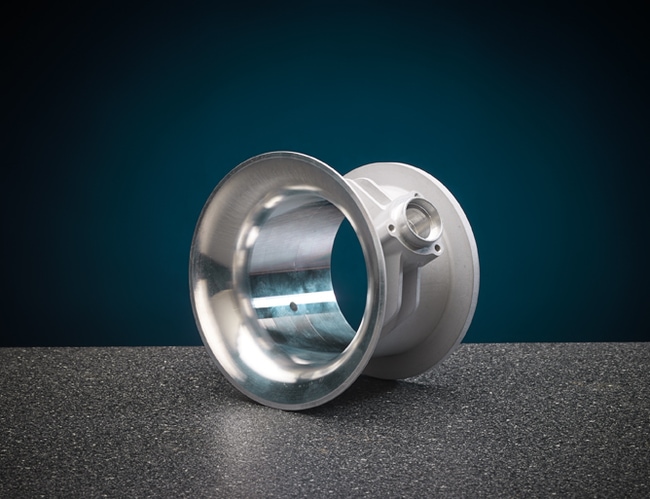

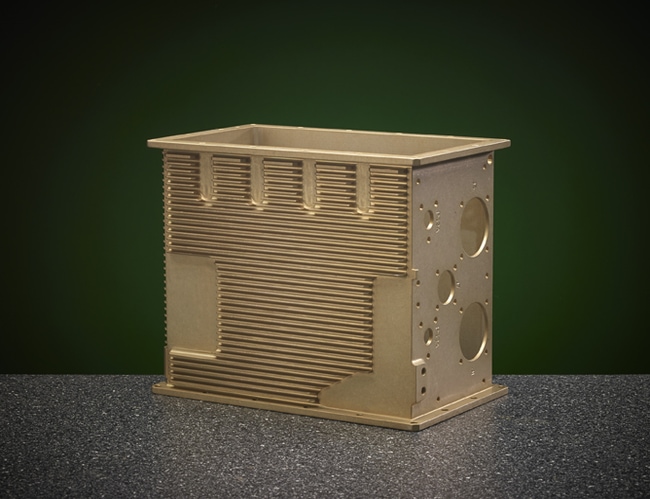

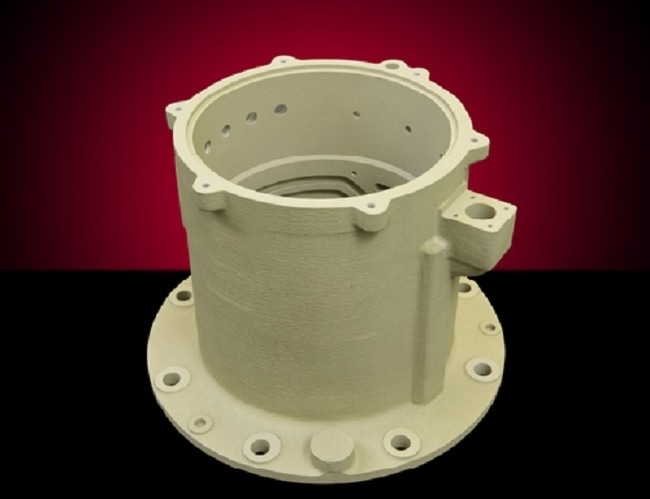

Mac Machine Company offers CNC machining, CNC milling, secondary services, and more. We are a one-stop-shop for industrial parts and we focus on high-quality productions. Our team has successfully fabricated parts for projects ranging from Honeywell jammer programs to Apache helicopters and surgical tools.

Our CNC Milling Capabilities

We specialize in high-quality milling projects with tight tolerances and complex designs. Our programming team analyzes every drawing and 3D model to find the best milling strategy for each design, and our advanced CAD system ensures every part is produced precisely to specifications.

Facility List:

5-Axis CNC:

Matsuura MAM72-35V w/ 32 Pallets and 320 Tool Holders

Matsuura MAM72-35V w/ 32 Pallets and 240 Tool Holders

Matsuura MAM72-63V w/ 6 Pallets and 240 Tool Holders

Matsuura MAM72-63V 50 Taper w/ 6 Pallets and 150 Tool Holders

(5) Fanuc Robo Drills aD14MiA5 10,000 RPM With Tsudakoma RTT-111 4th & 5th Axis Table

Okuma 4000MV w/ 6 pallets and 275 tool holders

4-Axis CNC:

2x Matsuura Horizontal Machining Center w/ 11 Pallets and 210 Tool Holders

Matsuura Horizontal Machining Center w/ 2 Pallets and 210 Tool Holders

Matsuura Horizontal Machining Center H.Plus-500 w/ 11 Pallets and 240 Tool Holders

Matsuura H-Plus 300 with 15 pallets

Manual Mills:

2x Bridgeport Milling Machines with Digital Readouts