Our wire electrical discharge machining (EDM) capabilities include lights-out production that maximizes efficiency and output. For our clients, this translates to reliably low costs and quick turnaround times regardless of project specifications.

Wire EDM Capabilities

Wire EDM is a reductive manufacturing process that removes material from a workpiece using recurring electrical charges between two electrodes. As such, this process is also frequently referred to as spark machining or spark eroding.

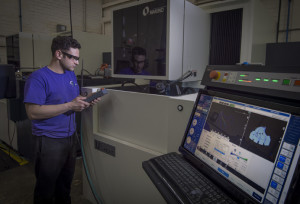

At Mac Machine Company, we rely on advanced wire EDM machines to meet the needs of our customers. Our wire EDM capabilities are as follows: